Parts of Vertical Milling Machine

Parts of Vertical Milling Machine

The vertical knee mill is the most common

milling machine found in machine shops today. Therefore it will be used as an

example to describe the general parts of all mills.

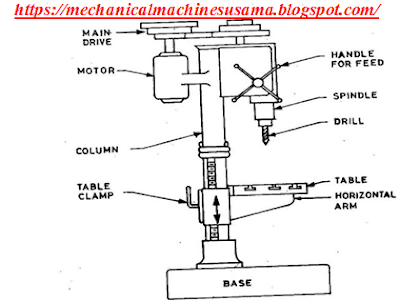

Head

The head (drive) is that part of the drive

system that transforms electrical power from a motor to mechanical power in the

spindle. The drive system also allows the machinist to change the speed of the

spindle (RPM) and therefore the cutting tool. The quill moves vertically in the

head and contains the spindle in which cutting tools are installed.

Column

The column is

the most important part which is mounted on the base and acts as a support and

holding device for all the other parts of a milling machine. It acts as a

support for table and all feed mechanisms. The column should be rigid enough to

sustain all the forces produced due to the drilling action of the tool. The head and worktable are mounted

with column.

Work table

It gives the motion in X-direction.

Saddle

It gives the motion in Y-direction.

Knee

It gives the motion in Z-direction.

The saddle sits on the knee and allows

translation of the worktable. Sitting on the base is the column whose main

function is to hold the turret. The turret allows the milling head to be

rotated around the column's center. The over arm (ram) slides on the turret and

allows the milling head to be repositioned over the table.

Base

The whole machine is mounted on

this part. The base is that part of a machine on which the

column is mounted. In the belt driven milling machines both the fast and loose pulley

and cone pulley are also mounted on the base. In general the base is of a

circular cross section when viewed from top. The base also has T-slots on it

facilitating holding of large pieces for machining.

Comments

Post a Comment