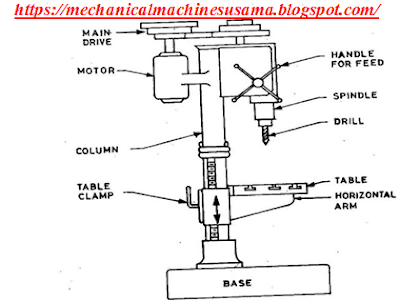

Study of major parts of Upright Drill Machine

Base:

The base is that part of a machine

on which the column is mounted.

The column is the most important part which is

mounted on the base and acts as a support and holding device for all the other

parts of an upright drilling machine. It acts as a support for table and all

feed mechanisms.

Table:

Table is the part on which the work piece is mounted. This is held up by

fixing it to a column. A table can have rectangular geometry or circular in

shape. Slots are provided on the table for holding the work piece very

effectively. Three types of movements of the table are provided so as to achieve

the centering very easily. The three movements incorporated in the table are

·

Vertical adjustment

·

Radial adjustment around the column

· Circular adjustment

about its own axis

Head:

Drill head is the one which holds all the feed

mechanisms and spindle drive motion. Drill head is mounted on the column. The head has a set of handles (usually 3)

radiating from a central hub that, when turned, move the spindle and chuck

vertically, parallel to the axis of the column. The drill press is typically measured

in terms of swing. Swing

is defined as twice the throat

distance, which is the distance from the center of the spindle to the

closest edge of the pillar.

For

most drill presses—especially those meant for woodworking or home use—speed

change is achieved by manually moving a belt across a stepped pulley arrangement. Some drill presses add

a third stepped pulley to increase the number of available speeds.

Spindle,

quill and drill head assembly:

Spindle is the part to

which the driller is connected. It acts as a linking pin in transfer of energy

form top shaft to the tool through the usage of bevel gears. A sliding key is

engaged in connection of pulley and the spindle. The spindle is surrounded by a

non rotating sleeve which is called as a quill. The vertical movement of the

spindle is obtained by engaging rack teeth which are cut on the outer surface

of the quill. In some of the precision machines a block contains rack teeth is

bolted to the outer surface of the quill. The lateral movement of the quill is

obtained by the engaging of a pinion to the rack teeth. A morse taper hole is

provided at the lower portion of the drill for the usage of taper shank drill.

This is very useful for holding small sized tools. When small sized tools are

employed then the taper shank drill is connected in which the smaller drill is

fixed hence helping in obtaining required high end

machining.

Spindle drives mechanism:

Spindle drive mechanism

is the sole reason for obtaining multiple speeds of spindle. These multiple

speeds of the spindle are obtained by three types

· Step cone pulley drive

· Step cone pulley drive

with one or more back gears

· Gearing

In a step cone pulley drive the multiple speeds

are obtained by the step cone which consists of various pulley sizes. This type

of mechanism is used in belt driven type of the upright drilling machines. In

the second case a step cone pulley drive along with back gears are engaged so

as to facilitate very low speeds which are generally used in precision works. Gears are used in most of the machines as the power transmission is

accurate and the size occupied is low.

Comments

Post a Comment